design for multi-scenario protection. Easily locks with one slide, securing products or

counters with reliable simplicity.

COMPATIBLE WITH 4A TECHNOLOGY

WHO WE ARE

Our Mission: Protecting Retail Value

Through Intelligent Manufacturing

Excellent quality and manufacturing precision

Reliable customer service and on-time support

Get Expert Insights on Smart EAS Solutions

Discover how SunPro makes EAS protection smarter and simpler.

PRODUCT RANGE

A diverse range of EAS and RFID solutions covering tags, antennas, detachers, and smart systems — designed to reduce retail loss, optimize store operations, and enhance customer engagement.

and loss prevention. This integration not only improves real-time visibility and stock accuracy

but also strengthens protection against theft—helping retailers operate smarter and more

efficiently.

4A solution without replacing existing detachers. This minimizes upgrade costs while delivering

stronger protection, smoother checkout, and enhanced loss prevention for retailers.

protect merchandise. Durable, reliable, and easy to integrate at any retail counter—enhancing

customer experience while reducing theft.

PRODUCTION PROCESS

Precision. Quality. Consistency.

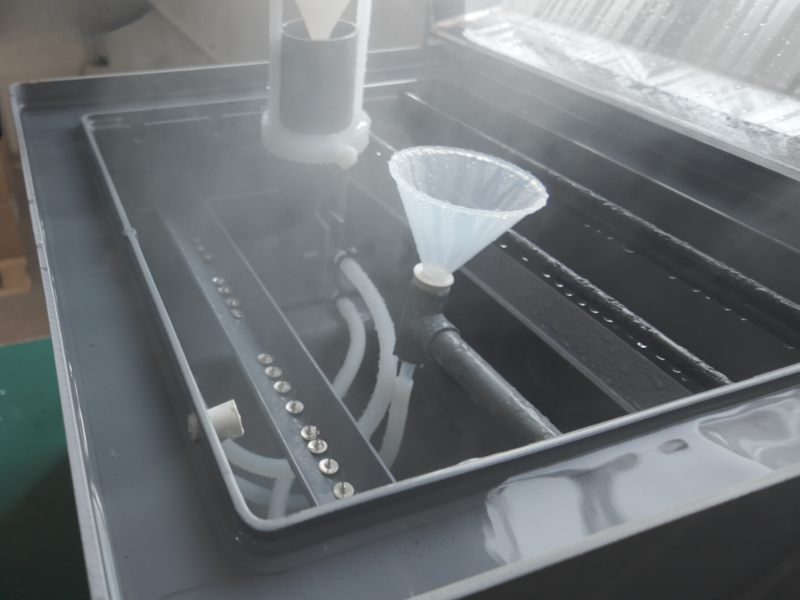

The coil production process is the foundation of any EAS tags. SunPro utilizes high-precision automatic winding and welding technology to ensure that every resonant coil meets strict frequency consistency and stability requirements. Each coil is precisely wound with ultra-fine copper wire and bonded under controlled tension to achieve optimal resonance performance at 8.2 MHz or 58 KHz, depending on the system type.

Through advanced testing and quality inspection, the produced coils deliver exceptional signal strength, low loss, and long-term reliability—providing a solid core for stable detection performance in retail security systems.

Frequency

Component

Injection molding is a key process in the production of EAS hard tags and housings. SunPro employs precision injection molding equipment to create durable and dimensionally consistent plastic shells that protect the internal resonant coil and ferrite components.

Using high-quality engineering polymers such as ABS and polycarbonate, each mold is designed to achieve superior strength, heat resistance, and impact durability. The precise control of temperature, pressure, and cooling cycles ensures smooth surface finishing and tight sealing performance, enabling the tag to withstand long-term use in various retail environments.

Injection

Molding

RFID encoding is a crucial step in integrating identification data into each electronic tag. SunPro utilizes advanced RFID encoding equipment to accurately write unique digital information—such as product ID, store code, or tracking data—into every RFID chip.

By combining high-speed encoding with strict quality inspection, SunPro guarantees consistent data reliability and excellent read performance, empowering retailers with smarter item-level tracking and enhanced loss prevention efficiency.

RFID

Encoding

RFID dual tag production combines the advantages of EAS and RFID technologies into a single, high-performance label. SunPro integrates advanced RFID inlay embedding and EAS resonant coil assembly to create dual-function tags that provide both electronic article surveillance and item-level identification.

During production, precise alignment and lamination processes ensure the optimal connection between the RFID chip and antenna, as well as the stable resonance of the EAS circuit. Each dual tag undergoes automated encoding, frequency tuning, and functional verification to guarantee consistent read performance and detection sensitivity.

RFID

Dual Tag

The assembly process is a vital stage in producing high-quality EAS and RFID tags. SunPro’s automated assembly machines precisely integrate multiple components—including frequency component, lock parts, and shells—into a single, compact, and durable unit.

Equipped with advanced positioning systems and vision-assisted alignment, the machines ensure accurate component placement and secure bonding. Automated adhesive dispensing, ultrasonic welding, and pressing steps are carefully controlled to maintain consistent quality and mechanical strength.

Assembly

Machinery

The assembly line at SunPro is dedicated to the production of functional tags and alarming nets, serving as a key process in EAS and RFID tag manufacturing. Unlike a fully automated system, this line relies on skilled operators who perform each step under strict process control to ensure consistency and reliability.

Each workstation follows standardized operating procedures, with emphasis on quality inspection and process discipline. The entire production area is built with ESD protection in mind—featuring anti-static epoxy flooring, grounding systems, and proper handling protocols—to prevent electrostatic discharge and guarantee the stability of electronic components.

Assembly

Line

Quality control is a cornerstone of SunPro’s manufacturing process, ensuring that every EAS and RFID product delivers stable performance and long-term reliability.

SunPro’s in-house laboratory is equipped with advanced testing instruments covering mechanical strength, electrical performance, and environmental durability. Key equipment includes automatic tensile and compression testers, network analyzers, salt spray test chambers, and inductance measurement systems. These tools enable comprehensive evaluation of product strength, frequency stability, corrosion resistance, and electrical accuracy.

Quality

Control

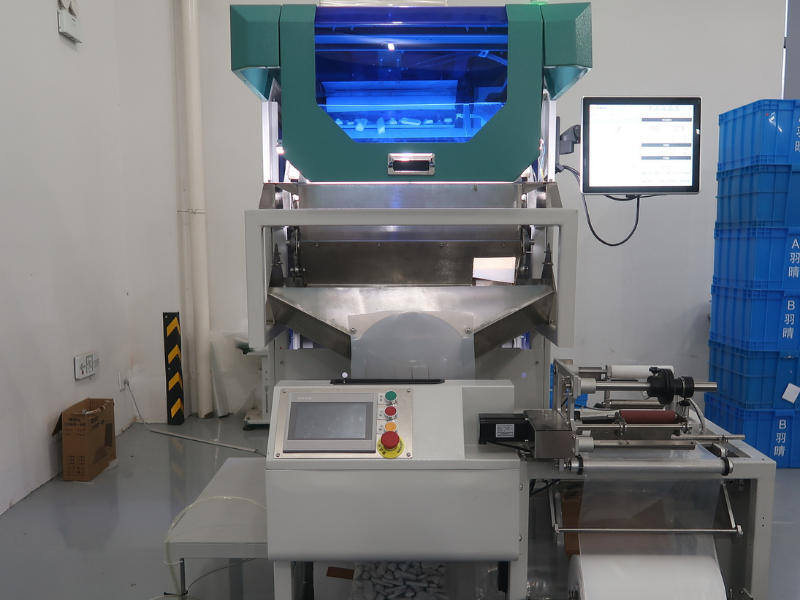

The vision recognition packaging machine plays a vital role in ensuring quantity accuracy during the packaging process. Equipped with high-precision cameras and intelligent counting algorithms, the system automatically verifies the number of EAS or RFID tags in each package before sealing.

This automated inspection eliminates the risk of shortages or miscounts, ensuring that every box contains the correct quantity according to customer specifications. The process significantly improves packaging reliability and efficiency while reducing manual errors and labor intensity.

Visualized

Bagging

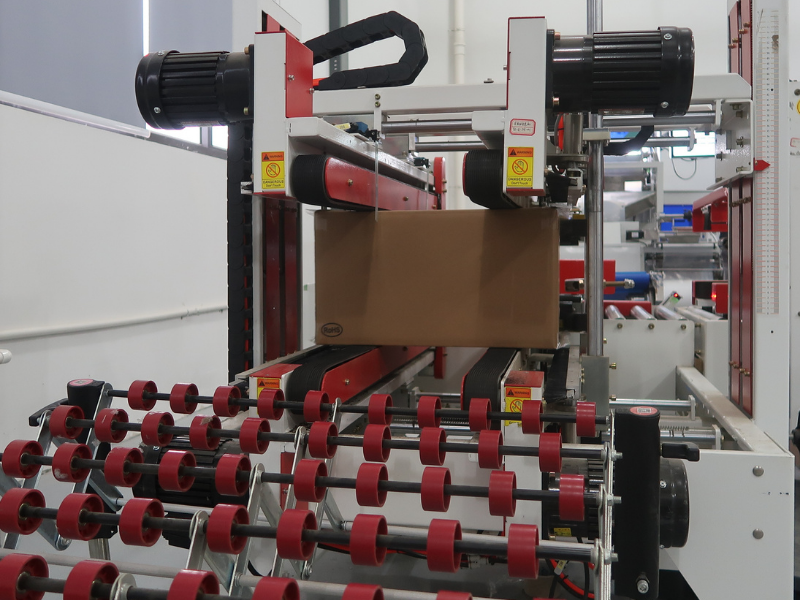

The automatic carton sealing machine ensures a consistent and professional finish for every shipment. Once the packaging is verified, boxes are automatically conveyed to the sealing station, where uniform tape application and firm sealing are performed according to SunPro’s quality standards.

This process guarantees that all cartons maintain a clean appearance, tight closure, and durable protection during transportation. The automated system also improves production efficiency and ensures every package meets the company’s uniform sealing requirements.

Carton

Sealing

The automatic palletizing machine completes the final step of the packaging process. It efficiently stacks sealed cartons onto pallets according to programmed patterns, ensuring stable, space-optimized, and secure arrangements for transportation.

With precise mechanical control and strong structural design, the palletizer provides firm and uniform stacking, reducing the risk of shifting or damage during shipment. This automation guarantees both efficiency and consistency, ensuring every batch of products is safely and neatly delivered to customers.

Smart

Palletizing

LATEST NEWS

Innovation, Growth & Company News

- Notice on SunPro's New Year's Day Holiday Arrangements for 2026

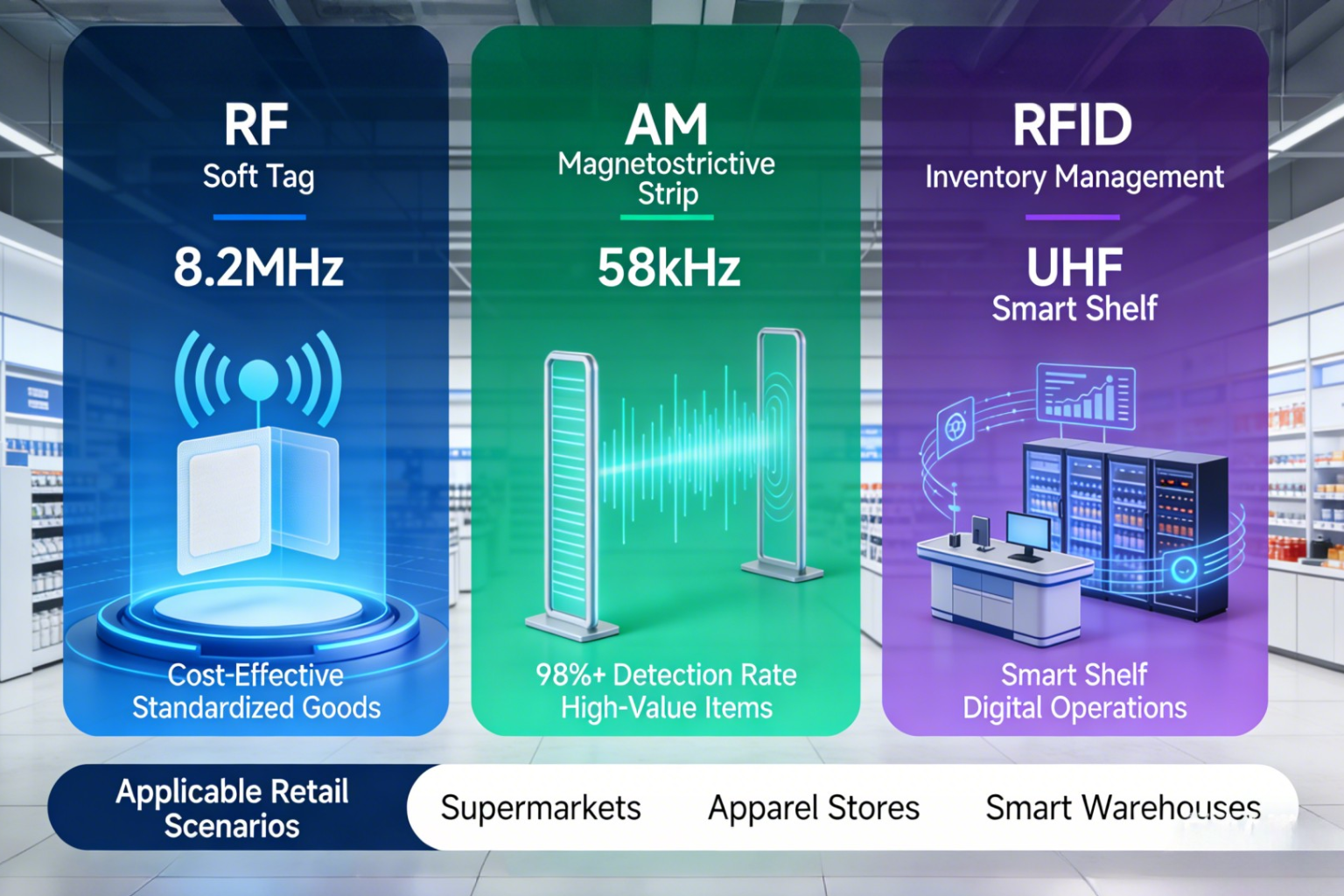

- Decoding EAS Core Technologies: How to Choose the Right Solution for Radio Frequency, Acousto-Magnetic, and RFID Systems Without Paying Over the Odds?

- Choose UHF for operational efficiency, HF/NFC for brand experience. The smartest choice is integrating both.

- Sunshine Protecting’s team building (barbecue/Monopoly) boosted cohesion for retail tech (EAS/RFID) progress.

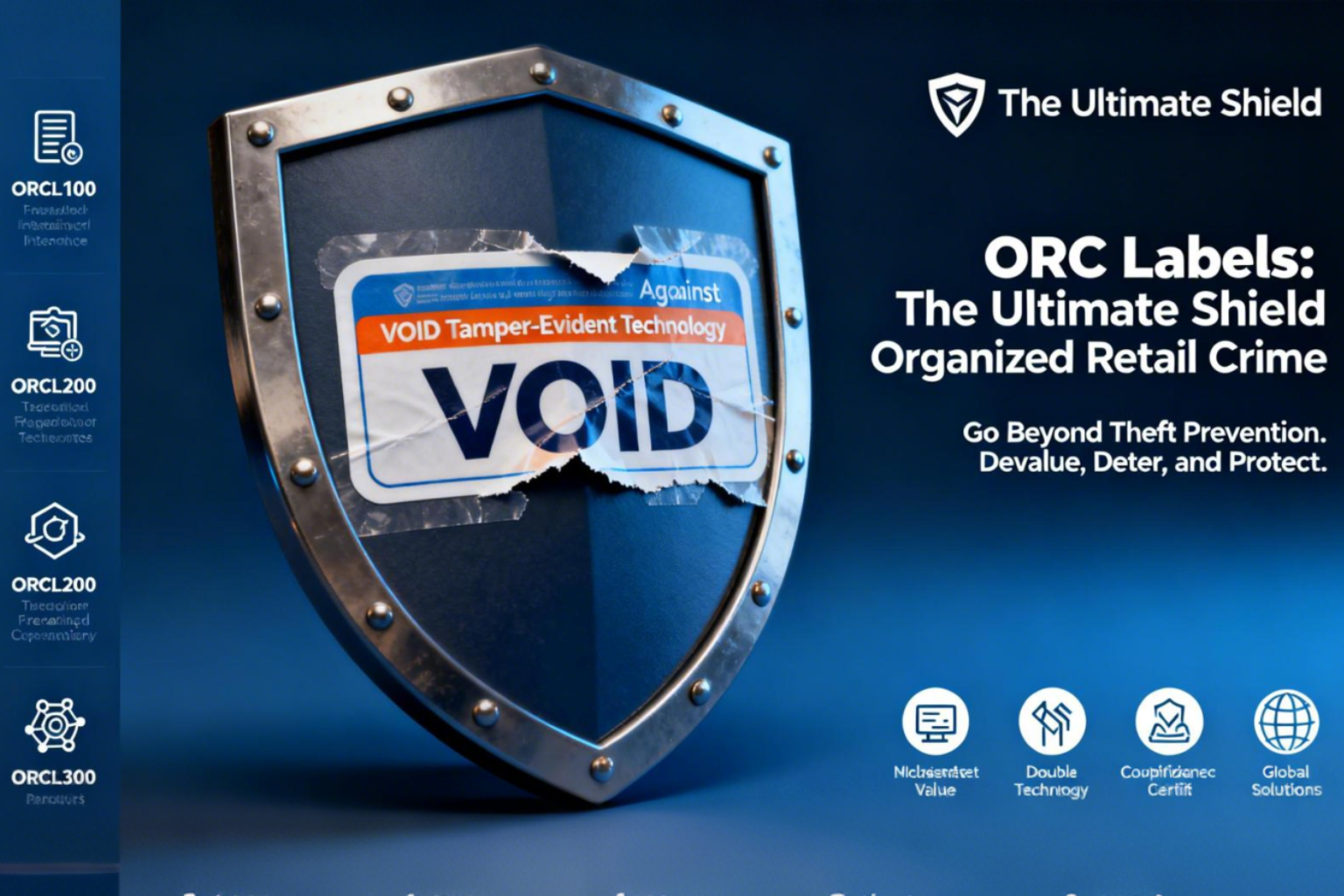

- SunPro ORC Labels: Tamper-evident, customizable security to eliminate ORC resale value and protect retail profits.